by Sam Browning

edited by Mike Elliott, Kettle River Canoes

email: artisan@canoeshop.ca

Note: In 2016, I put out a call for someone with a wide-board raised-batten canoe to bring it to my shop in British Columbia, Canada for me to restore and document as part of my second book ̶ “This Fancy Old Canoe”.

I was contacted immediately by Sam Browning. He was about to start restoring one of these canoes. He offered to take pictures of the project as he worked. I offered to come to his shop to see the canoe and meet him in person until he let me know he lived in Ely, Cambridgeshire, England.

A few months later, I received a USB flash drive in the mail from Sam. It contained 300 images and a copy of the posts he presented on the ‘Song of the Paddle’ web forum as he documented the restoration. For my blog (and eventually my book), I have edited Sam’s posts and added a few notes of my own (presented in italics). For this article, I am presenting the rib repairs as well as some general history and description of the canoe.

Many thanks to Sam for his excellent work and generous contribution to my book.

*****************

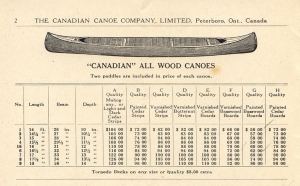

My canoe was made by the Canadian Canoe Company in Peterborough, Ontario. The company started in 1892. The last canoes of this type were built around the mid 1930’s. From the 1929 catalogue, my canoe is the 15′ 6″ No. 4 all wood canoe F quality (varnished, basswood boards). It has a 29½” (75 cm) beam and a depth of 11½” (29 cm) amidships. It is interesting to note that the garboards (the two planks on the bottom of the canoe) in my canoe are Spanish cedar ̶ a true mahogany.

This particular canoe was imported to England by Salter Bros. Ltd. of Oxford. Looking at the Salter Bros. history, they mention importing 21 canoes from Canada in 1930. My canoe may be one of those.

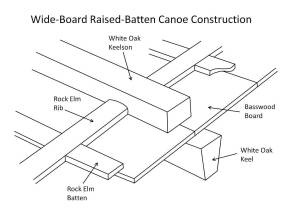

The exact origin of wide-board raised-batten canoe construction on a solid wood form is up for debate, but it was probably developed in a combined effort by Tom Gordon and John Stephenson in 1857. Construction began by laying down a white oak keelson. Rock elm ribs were then bent over the form and fitted into notches cut into the keelson. Wide basswood boards (three or four on each side) ran longitudinally and were attached to the ribs with copper canoe nails. Nail holes were pre-drilled and the nails were driven straight into the solid-wood form. The hull was then pulled free of the form and turned right-side up.

The nails were then ‘dubbed’ (bent over) to lie flat along the ribs (with the points towards the keelson) and then clinched tight with a clinching iron and cobblers hammer. The seams between the basswood boards were covered with ironwood battens between the ribs held in place with copper canoe nails.

If this was a cedar-canvas canoe with damaged ribs, I’d just take them out and replace them. With one of these canoes, you can’t do that without taking the whole thing apart. What I plan to do is bend new rib material which will extend from the keelson to the sheer-line and nail it in place alongside the existing rib (this process is commonly used in wooden boat repair and is known as sistering ribs).

Because the canoe has had broken ribs for many years, it needs a bit of reshaping before I can bend and install the new rib material. Straps around the canoe with a couple of lengths of timber to push in the right places helps to reshape.

I bend the new rib material inside (straight-grained english oak cut to size and shaped to replicate the original before it is soaked overnight and steamed for an hour), on top of the old rib. Any spring-back should result in the right size and curve. The end of the new rib at the keelson is held in place by a scrap piece of hardwood wedged between it and a length of timber positioned above the keelson and clamped on top of the thwarts. The rest of the new rib is held in place with g-clamps (c-clamps) and spring clamps. This process is facilitated by the fact that one of the basswood planks is missing. The missing plank allows me to use a couple of spring clamps to hold it in the middle.

Once the new rib has dried overnight, I decided to cut the battens first as it has to be easier than removing them and installing new ones. With over ten copper nails dubbed and clinched in each batten, it would be impossible to remove them in one piece, and they do have to fit exactly. I cut the battens with an inlay saw (3″ or 76 mm blade with 20 teeth per inch and a 0.011″ or 0.3 mm kerf). Its curved blade allows me to remove a small piece of the batten with less chance of damaging the planks.

The battens are carefully marked and cut. I have to make sure the plank is clean where the new rib will go. I clamp the rib in position making sure it fits well against the keelson and the original rib.

When the new rib is in place, I drill a pilot hole through the rib and plank at the centre of each rib. Then, I push a 19 mm (¾”) copper canoe nail in from the outside. The nail is then dubbed towards the keelson and clinched tight. Then, I pilot, dub and clinch three more nails into each plank as well as one at each batten. I cut the rib flush with the sheer-line and shape the rib-top to match the existing ribs.

At the gap, where the broken rib is exposed, I cut it off in line with the battens.

In some sections, retention of the original hull shape was facilitated by clamping a hardwood batten on the outside of the exposed original ribs.

The broken sections of original rib were cut away with the inlay saw as well as the sections of batten required to allow for positioning of the new rib which was then soaked, steamed and clamped in place.

A total of twelve broken ribs were sistered in this canoe. The ribs were repaired in stages, doing every second rib along the length of the canoe in order to maintain the shape of the hull as much as possible.

The entire restoration process (including rib repairs and replacement) is described in my book – This Old Canoe: How To Restore Your Wood Canvas Canoe.

If you live in Canada, CLICK HERE to buy the book.

If you live in the USA, CLICK HERE to buy the book.

If you live in the UK, CLICK HERE to buy the book.

Si vous habitez en France, CLIQUEZ ICI acheter le livre.

If you have read the book, please post a review on Amazon, Goodreads and/or any other review site.